The following content contains excerpts from interviews with team members from BW Flexible Systems and Synerlink, which originally appeared in a Cheese Market News Packaging Progress Profile ahead of Pack Expo International on October 21, 2022.

As Barry-Wehmiller’s global team of packaging professionals, BW Packaging is best known for its reputation of caring for people and its broad range of high-performance packaging solutions. Comprised of five divisions — Accraply, BW Flexible Systems, BW Integrated Systems, Pneumatic Scale Angelus and Synerlink — BW Packaging Systems offers comprehensive packaging machinery and solutions including complete packaging lines, filling and closing, flexible packaging, labeling, end-of-line solutions and systems integration.

At the 2022 Pack Expo tradeshow in Chicago, BW Packaging experts showcased some of the company’s newest innovations for cheese packaging, including its Hayssen ISB vertical form-fill-seal (VFFS) bagger and Versatech cup filling machine. Here is what Cheese Market News Editor-in-Chief Alyssa Mitchell had to say about these solutions.

The Hayssen ISB VFFS Bagger by BW Flexible Systems

According to Dan Minor, global product line leader for VFFS solutions at BW Flexible Systems — a division of BW Packaging — the Hayssen ISB offers the highest levels of sanitary design and construction available in the market today.

“With an overall rating of IP66, the machine is designed to withstand direct high-pressure washdown and the aggressive sanitizing agents required to ensure food safety,” Minor notes. “With extensive use of precision servo controls, the Hayssen ISB offers film and product feeding features uniquely suited to handle the ever-changing range of sustainable packaging films.”

The Hayssen ISB is ideally suited for packaging fresh or chilled shredded, grated or cubed cheeses into foodservice and retail packs. It takes hygienic design, cleanability, performance and ease of use to a new level for cheese packaging, Minor adds.

The machine design was based on the most recent industry standards for dairy, meat, produce and RTE (ready to eat) applications, notes Margaret Valinski, director of VFFS sales, North America, for BW Packaging.

The machine design was based on the most recent industry standards for dairy, meat, produce and RTE (ready to eat) applications, notes Margaret Valinski, director of VFFS sales, North America, for BW Packaging.

“Minimizing harborage points for contamination and accessibility for cleaning was a priority,” Valinski says.

Read Dan and Margaret’s full interviews with Cheese Market News on the BW FlexibleBW Flexible Systems’ blog Systems’ blog.

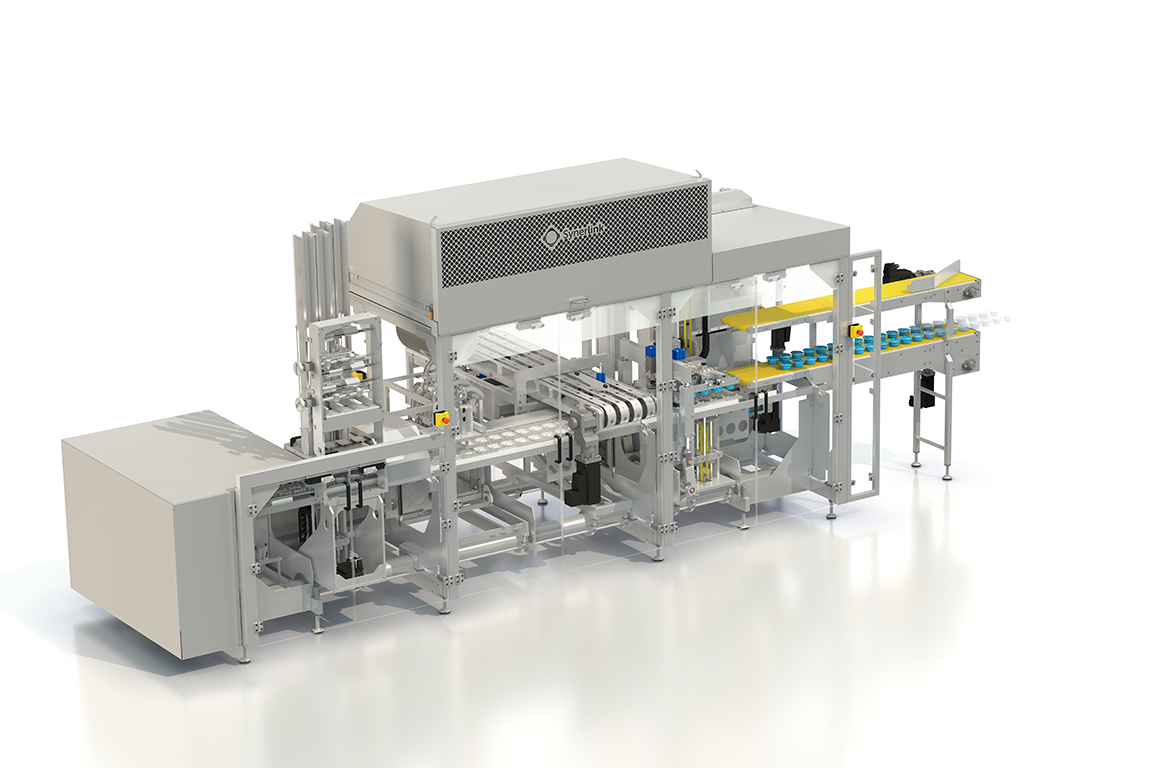

The Endlessly Flexible Versatech by Synerlink

Synerlink, another BW Packaging division, also showcased an immersive 3D view of Versatech, the company’s latest filling solution for the food and dairy industry, at Pack Expo. Versatech’s modular design enables customers to continually realign this machine with their evolving business strategy, solving the market need for a filling solution that can outlast the standard 20- to 30-year life cycle.

Fabien Jégo, design and product marketing leader at Synerlink S.A., says keeping up with the latest innovations in product packaging can be difficult without the right packaging machinery.

“Our innovative Versatech machine is designed to adapt to the market and keep an eye on the future without hindering the efficiency or scalability of production — all at the same time,” he says.

The concept was built with flexibility in mind, he adds.

“Synerlink’s long experience in the industry and continuous engineering studies allow us to build a machine that responds to all your needs. Synerlink’s Versatech cup-filling machine is engineered to fill a wide variety of processing cups while minimizing changeover time and maximizing your production efficiency. Thanks to the automatic loading and unloading of slats, the change in production is efficient and optimized,” Jégo says.

To read the entire Packaging Progress profile written by Cheese Market News Editor-in-Chief Alyssa Mitchell, visit cheesemarketnews.com.