Sustainable Shrink Sleeve Trends

As today's brand owners continue to seek circular packaging solutions for their products, labeling suppliers must also evaluate how their films support or discourage proper recycling habits. While downgauging continues to be a valid strategy for reducing

plastic waste, fully recyclable label solutions such as floatable and crystallizable films present new possibilities for responsible manufacturers.

In this post, I’ll introduce you to basic resources for understanding plastic label recyclability, highlight some exciting new developments in sustainable shrink sleeve technology, and present new equipment that makes it possible to introduce these

innovations to the market at scale.

Understanding Plastic Recyclability

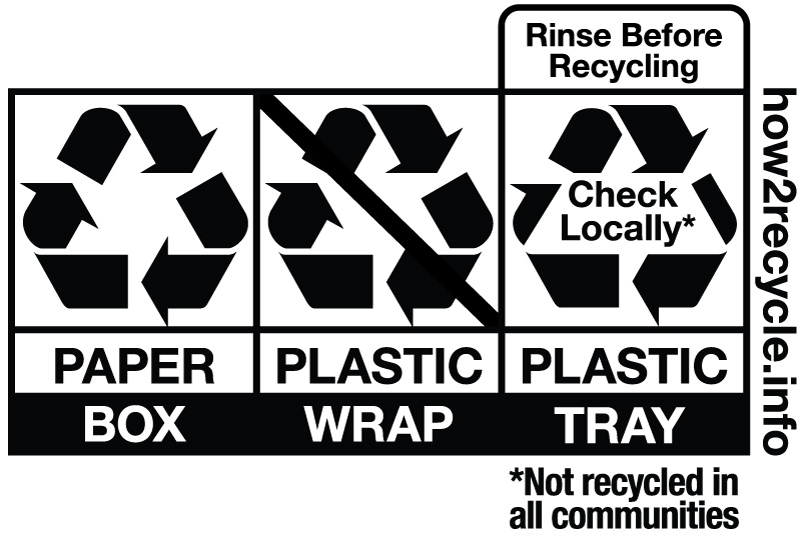

When it comes to understanding the recyclability of product packaging and labels, what better place to start than the containers themselves? Thanks to an organization called How2Recycle, consumers are better equipped than ever before to properly recycle

labels and packaging. Brand owners that partner with How2Recycle display the How2Recycle® label on their packaging, making it clear exactly how to recycle each part of the package from primary to secondary packaging and even the label. For labeling

converters, familiarizing yourself with How2Recycle’s standard instructions is a good first step.

The Association of Plastic Recyclers (APR), an international trade association representing the plastics recycling industry, is another valuable resource. APR publishes consensus-based guidelines called APR Design® Guides that can help labeling converters understand the attributes of recyclable films and materials so they can design sustainable labeling solutions. APR offers guidance for PET, HDPE, PVC, PE and every

other plastic you can think of.

Innovations in Sustainable Labeling Technology

Last summer, Plastics Recycling Update highlighted three PET shrink label products that met APR’s recyclability

guidelines. The first, Siegwerk’s solvent-based washable inks, make it possible to recycle clean label film alongside PET bottles by easily washing off the crystallizable co-polyester shrink film. Similarly, Garware Polyester’s PETG shrink

label uses a washable HP Indigo ElectroInk, which after washed off, allows for the crystallizable co-polyester film label to be recycled alongside the PET.

Also on the list, CCL Label’s floating polyolefin shrink label – which they call Ecofloat – floats away from PET in float-sink tanks. When this happens, inks remain on the label to avoid significant staining to the clear PET flakes.

Alongside Synerlink, a BW Packaging company, CCL Label was also selected as a one of four Sustainability Awards Finalist in the machinery category for their Hybrid ASD technology.

While each of these innovations are exciting to say the least, their potential can’t fully be realized unless label converters find a way to apply them to their products at scale.

Converting Solutions for Sustainable Shrink Sleeve Films

To support the broader implementation of sustainable shrink sleeve innovations, Accraply partners with label suppliers to test and validate their solutions on shrink sleeve converting machines. Through innovative converting equipment like the Accraply Revolve, we convert recyclable films and adjust where necessary to reduce tension and ensure a seamless shrink-sleeving process. Our solutions make it possible for manufacturers to apply fully recyclable shrink

sleeve labels without compromising production or shelf appeal.

Accraply Revolve

The Accraply Revolve line includes three machines with various capabilities, but one ultimate goal: Enhance Productivity. Revolve machines has an intuitive design that reduces operator dependency and enables you to streamline and improve your operations. View

the Accraply Revolve product page for more information about this solution.